Blog

Blog

Nov 2024

All the Printing Techniques You Need to Know

#PrintingTechniques #Production

Nov 2024

All the Printing Techniques You Need to Know

#PrintingTechniques #Production

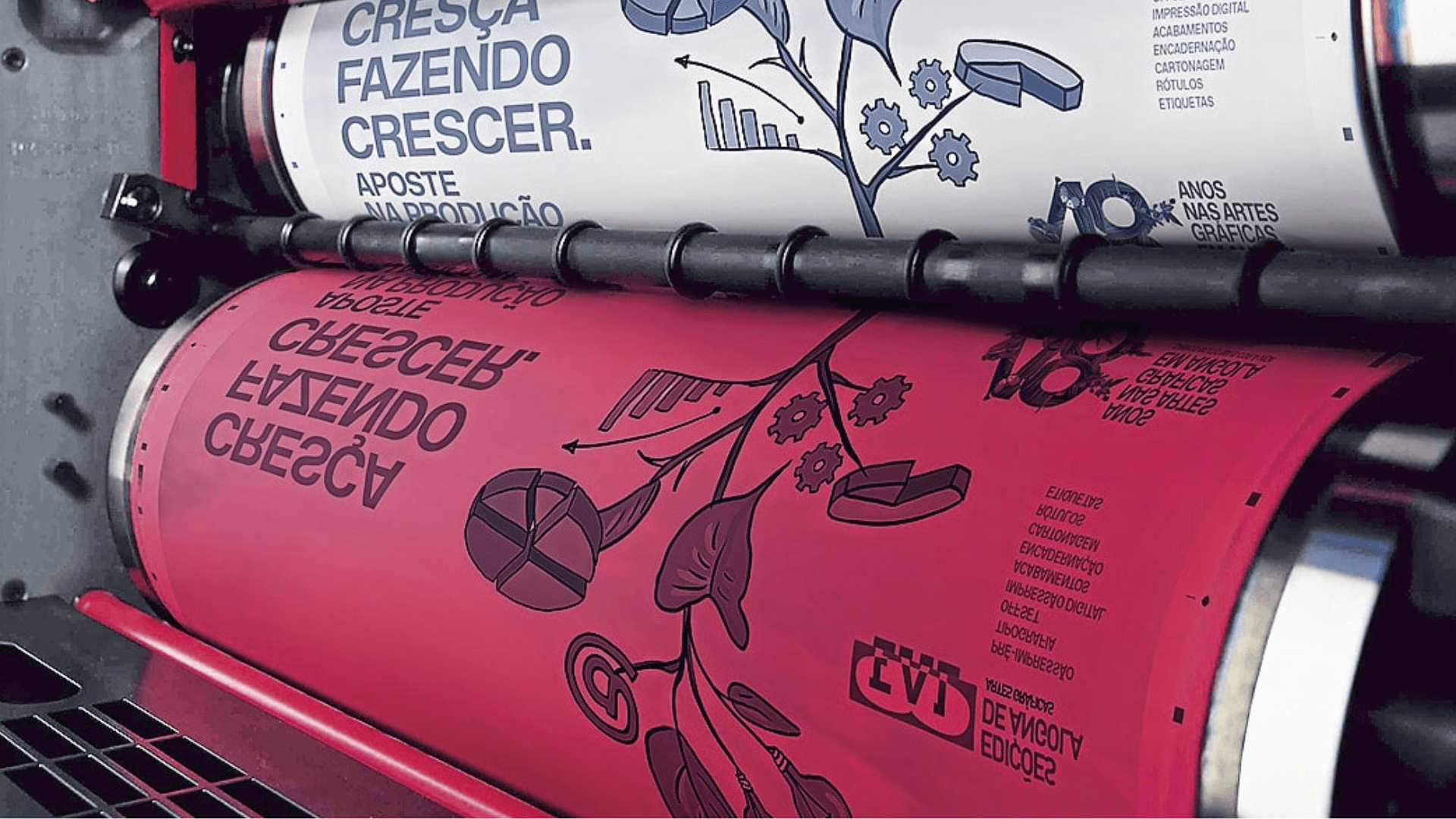

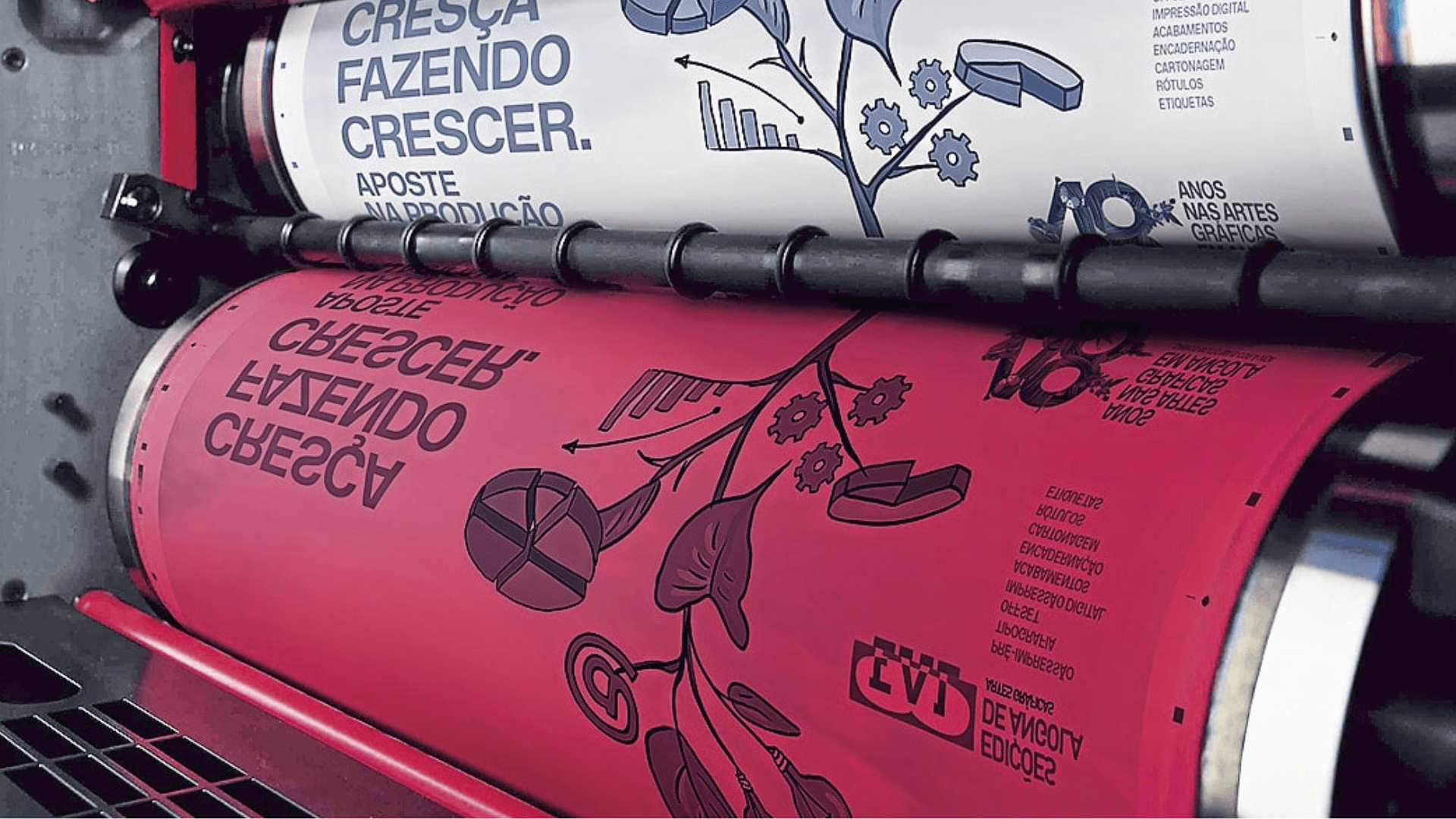

OFFSET PRINTING

Offset printing is one of the most traditional and widely used techniques in the graphic industry. It is the method typically chosen when large-scale productions are needed, commonly for items such as books, magazines, and brochures.

How it works: The ink is transferred from a plate to a rubber roller, and then to the paper. The process is called “offset” because the ink is not applied directly from the plate to the paper.

Advantages:

- High and consistent image quality.

- Great for large volumes (economically viable).

- Can print on various types of paper and surfaces.

Disadvantages:

- High initial setup costs.

- Not viable for small print runs due to the cost.

Ideal Application: Magazines, newspapers, books, large volumes of brochures, and other high-volume materials.

“The choice of the ideal technique depends on the production volume, type of material, budget, and the desired effect.”

PRINTING SILKSCREEN

Silkscreen Printing (Serigraphy) is a common technique used when printing on surfaces other than paper, such as fabrics, wood, plastic, and metal.

How It Works: Ink is pressed through a screen (a type of stencil), allowing it to pass only through specific areas of the surface, forming the design.

Advantages:

- Excellent for irregular surfaces and unconventional materials;

- Vibrant colors with high durability.

Disadvantages:

- Slower process, especially for large runs;

- Not recommended for works with intricate details.

Ideal Application: T-shirts, fabrics, product packaging, advertising materials on various surfaces.

Printing in Letterpress

Letterpress is a relief printing technique that involves pressing a plate against paper, resulting in a high-quality print with texture. This technique is highly appreciated for luxury productions, such as wedding invitations.

How It Works: A raised plate is pressed against the paper, creating an impression with depth.

Advantages:

- Unique appearance and texture;

- Traditional and sophisticated style.

Disadvantages:

- Longer production time;

- High cost.

Ideal Application: Packaging, labels, tags, plastic bags, and cardboard boxes.

DIGITAL PRINTING

Digital Printing is one of the most modern techniques, popularized for its versatility and speed. Unlike offset printing, which uses plates, digital printing is done directly from the file to the printer, in a process similar to an office printer.

How It Works: Digital printing uses a digital file and liquid ink or toner, applied directly onto the paper.

Advantages:

- Ideal for small print runs;

- Fast and with low initial cost;

- Allows for personalization of each print (variable data).

Disadvantages:

- Higher cost for large volumes;

- Slightly lower image quality compared to offset, especially in large formats.

Ideal Application: Business cards, personalized brochures, print proofs, and small print runs of magazines and catalogs.

Flexographic Printing

Flexography is a relief printing technique commonly used in packaging and labels. It uses flexible plates made of rubber or polymer, allowing printing on various materials.

How It Works: Ink is applied to a flexible plate, which then transfers the image to the chosen material.

Advantages:

- High production speed;

- Flexible for printing on plastics, papers, and other surfaces.

Disadvantages:

- Limited in reproducing fine details;

- Requires time to create the plates.

Ideal Application: Packaging, labels, tags, plastic bags, and cardboard boxes.

Sublimation

Sublimation is a popular printing method for transferring images to fabrics and synthetic materials, such as mugs and phone cases. It is a technique that offers excellent durability, as the ink is infused into the material.

How It Works: The image is printed onto transfer paper and then heated so the ink turns into gas and is fixed onto the material.

Advantages:

- Vibrant colors and high durability;

- Ideal for synthetic and personalized materials.

Disadvantages:

- Limited to surfaces with polymers (does not work on cotton, for example);

- Requires specialized equipment.

Ideal Application: Packaging, labels, tags, plastic bags, and cardboard boxes.

These graphic printing techniques offer solutions for a variety of project types. The choice of the ideal technique depends on production volume, material type, budget, and the desired effect. Regardless of the technique chosen, understanding the process and the possibilities each one offers is essential to ensuring the final product is of high quality and meets expectations.

OFFSET PRINTING

Offset printing is one of the most traditional and widely used techniques in the graphic industry. It is the method typically chosen when large-scale productions are needed, commonly for items such as books, magazines, and brochures.

How it works: The ink is transferred from a plate to a rubber roller, and then to the paper. The process is called “offset” because the ink is not applied directly from the plate to the paper.

Advantages:

- High and consistent image quality.

- Great for large volumes (economically viable).

- Can print on various types of paper and surfaces.

Disadvantages:

- High initial setup costs.

- Not viable for small print runs due to the cost.

Ideal Application: Magazines, newspapers, books, large volumes of brochures, and other high-volume materials.

“The choice of the ideal technique depends on the production volume, type of material, budget, and the desired effect.”

PRINTING SILKSCREEN

Silkscreen Printing (Serigraphy) is a common technique used when printing on surfaces other than paper, such as fabrics, wood, plastic, and metal.

How It Works: Ink is pressed through a screen (a type of stencil), allowing it to pass only through specific areas of the surface, forming the design.

Advantages:

- Excellent for irregular surfaces and unconventional materials;

- Vibrant colors with high durability.

Disadvantages:

- Slower process, especially for large runs;

- Not recommended for works with intricate details.

Ideal Application: T-shirts, fabrics, product packaging, advertising materials on various surfaces.

Printing in Letterpress

Letterpress is a relief printing technique that involves pressing a plate against paper, resulting in a high-quality print with texture. This technique is highly appreciated for luxury productions, such as wedding invitations.

How It Works: A raised plate is pressed against the paper, creating an impression with depth.

Advantages:

- Unique appearance and texture;

- Traditional and sophisticated style.

Disadvantages:

- Longer production time;

- High cost.

Ideal Application: Packaging, labels, tags, plastic bags, and cardboard boxes.

DIGITAL PRINTING

Digital Printing is one of the most modern techniques, popularized for its versatility and speed. Unlike offset printing, which uses plates, digital printing is done directly from the file to the printer, in a process similar to an office printer.

How It Works: Digital printing uses a digital file and liquid ink or toner, applied directly onto the paper.

Advantages:

- Ideal for small print runs;

- Fast and with low initial cost;

- Allows for personalization of each print (variable data).

Disadvantages:

- Higher cost for large volumes;

- Slightly lower image quality compared to offset, especially in large formats.

Ideal Application: Business cards, personalized brochures, print proofs, and small print runs of magazines and catalogs.

Flexographic Printing

Flexography is a relief printing technique commonly used in packaging and labels. It uses flexible plates made of rubber or polymer, allowing printing on various materials.

How It Works: Ink is applied to a flexible plate, which then transfers the image to the chosen material.

Advantages:

- High production speed;

- Flexible for printing on plastics, papers, and other surfaces.

Disadvantages:

- Limited in reproducing fine details;

- Requires time to create the plates.

Ideal Application: Packaging, labels, tags, plastic bags, and cardboard boxes.

Sublimation

Sublimation is a popular printing method for transferring images to fabrics and synthetic materials, such as mugs and phone cases. It is a technique that offers excellent durability, as the ink is infused into the material.

How It Works: The image is printed onto transfer paper and then heated so the ink turns into gas and is fixed onto the material.

Advantages:

- Vibrant colors and high durability;

- Ideal for synthetic and personalized materials.

Disadvantages:

- Limited to surfaces with polymers (does not work on cotton, for example);

- Requires specialized equipment.

Ideal Application: Packaging, labels, tags, plastic bags, and cardboard boxes.

These graphic printing techniques offer solutions for a variety of project types. The choice of the ideal technique depends on production volume, material type, budget, and the desired effect. Regardless of the technique chosen, understanding the process and the possibilities each one offers is essential to ensuring the final product is of high quality and meets expectations.

Articles You Can't Miss

5 Christmas Hamper Ideas to Strengthen Bonds and Partneships”

Blog Home | Blog| WINE LABELS 2024 5 Christmas Hamper Ideas to Strengthen Bonds and Partnerships#ChristmasHampers #Branding #SelectionAndProduction A well-thought-out

Everything You Need to Know About Printing Techniques

Blog Blog Home | Blog| Printing Techniques Nov 2024 All the Printing Techniques You Need to Know #PrintingTechniques #Production Graphic

Articles You Can't Miss

5 Christmas Hamper Ideas to Strengthen Bonds and Partneships”

Blog Home | Blog| WINE LABELS 2024 5 Christmas Hamper Ideas to Strengthen Bonds and Partnerships#ChristmasHampers #Branding #SelectionAndProduction A well-thought-out

Everything You Need to Know About Printing Techniques

Blog Blog Home | Blog| Printing Techniques Nov 2024 All the Printing Techniques You Need to Know #PrintingTechniques #Production Graphic